-

10+

Years of research

-

900x

Faster diagnostics

-

10x

Efficiency

-

85-100%

Less CO2 emissions

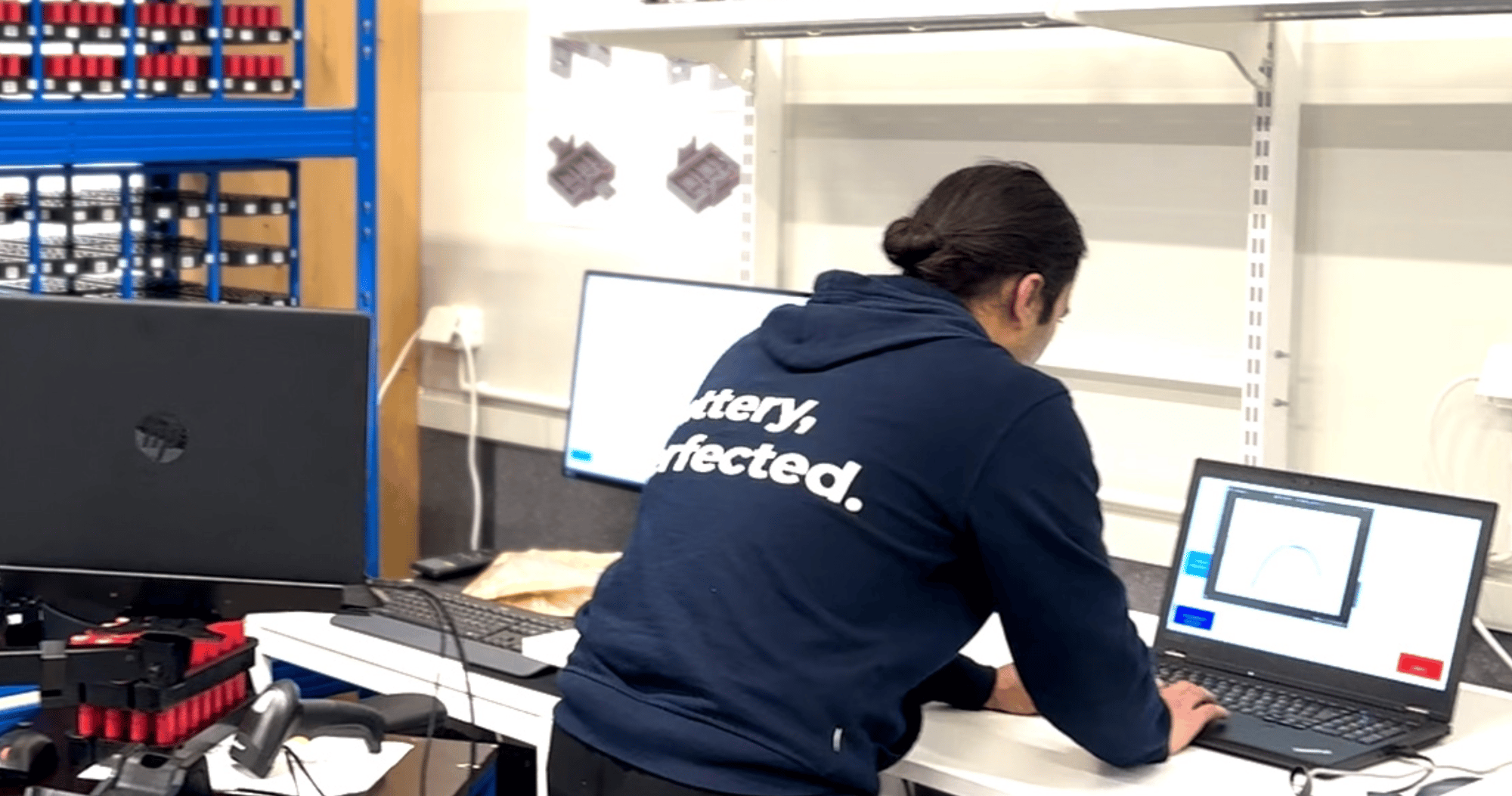

Unmatched battery quality fully integrated into your process

Accelerate your time-to-market with the fastest and the most accurate diagnostics solution in the market

seamlessly integrated into your automation systems.

Trustworthy and reliable batteries

We provide a scalable and integrated measurement and diagnostics system that ensures your batteries are top-notch quality. Our solution is suited for any kind of cell or battery and can be fully tailored to match your specific needs and ensure reliable batteries.

Meet the strict industry standards

The customizable battery diagnostics solution and measurement hardware enables advanced diagnostics for battery cells and packs, making sure you stay on top of the requirements and quality standards, and detect defects early.

.png?width=2000&height=1053&name=Untitled-7%20(1).png)

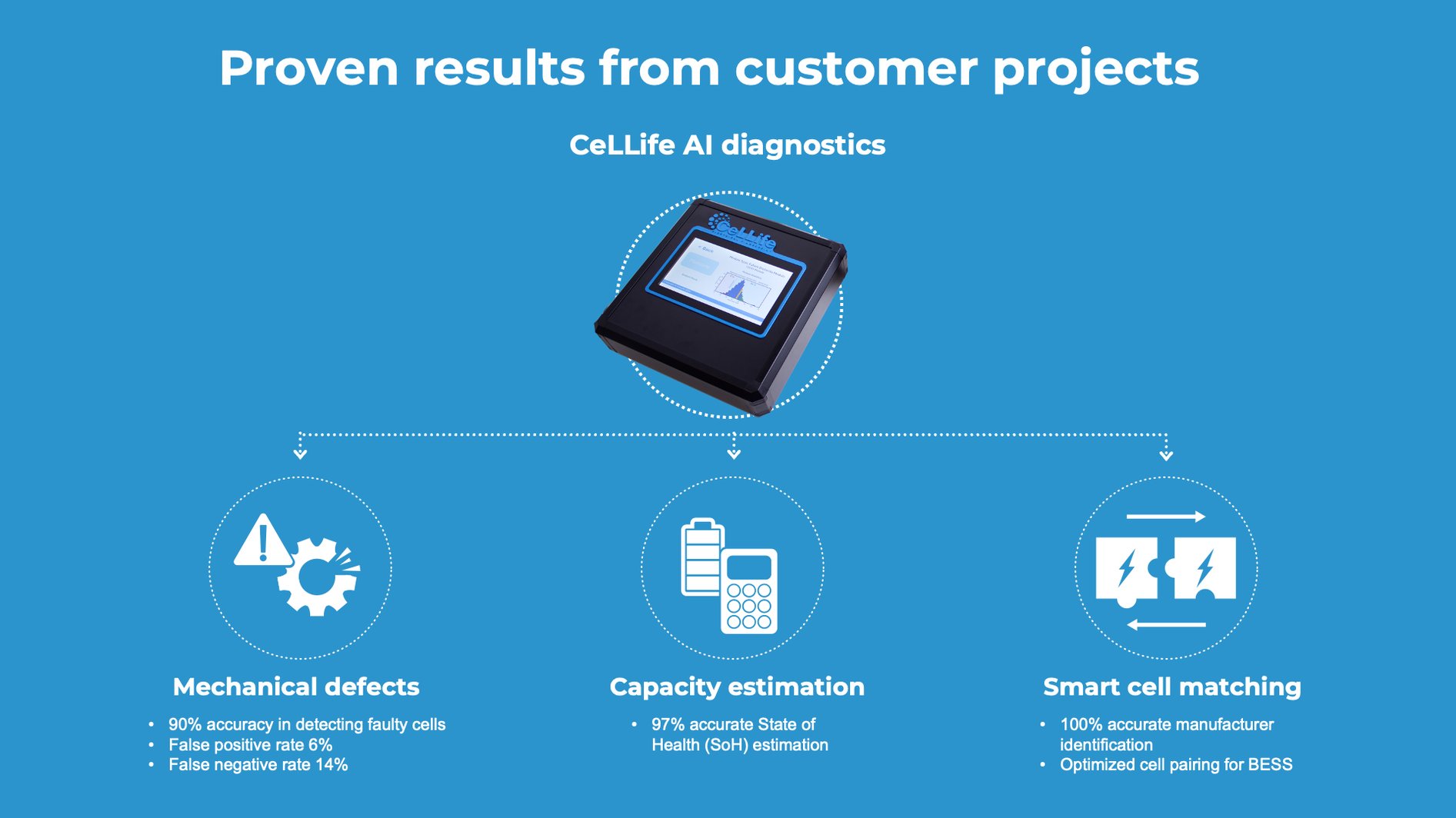

Constantly improve with the AI-driven diagnostics

Learn from your own operations by leveraging the smart predictions and insightful, easy-to-modify dashboards, helping to trace root causes. CeLLife AI powered-solution features advanced analytics for anomaly detection, defect severity analysis, and lifecycle tracking. Quickly perform tests and improve your products with comprehensive diagnostics and data.

Applications

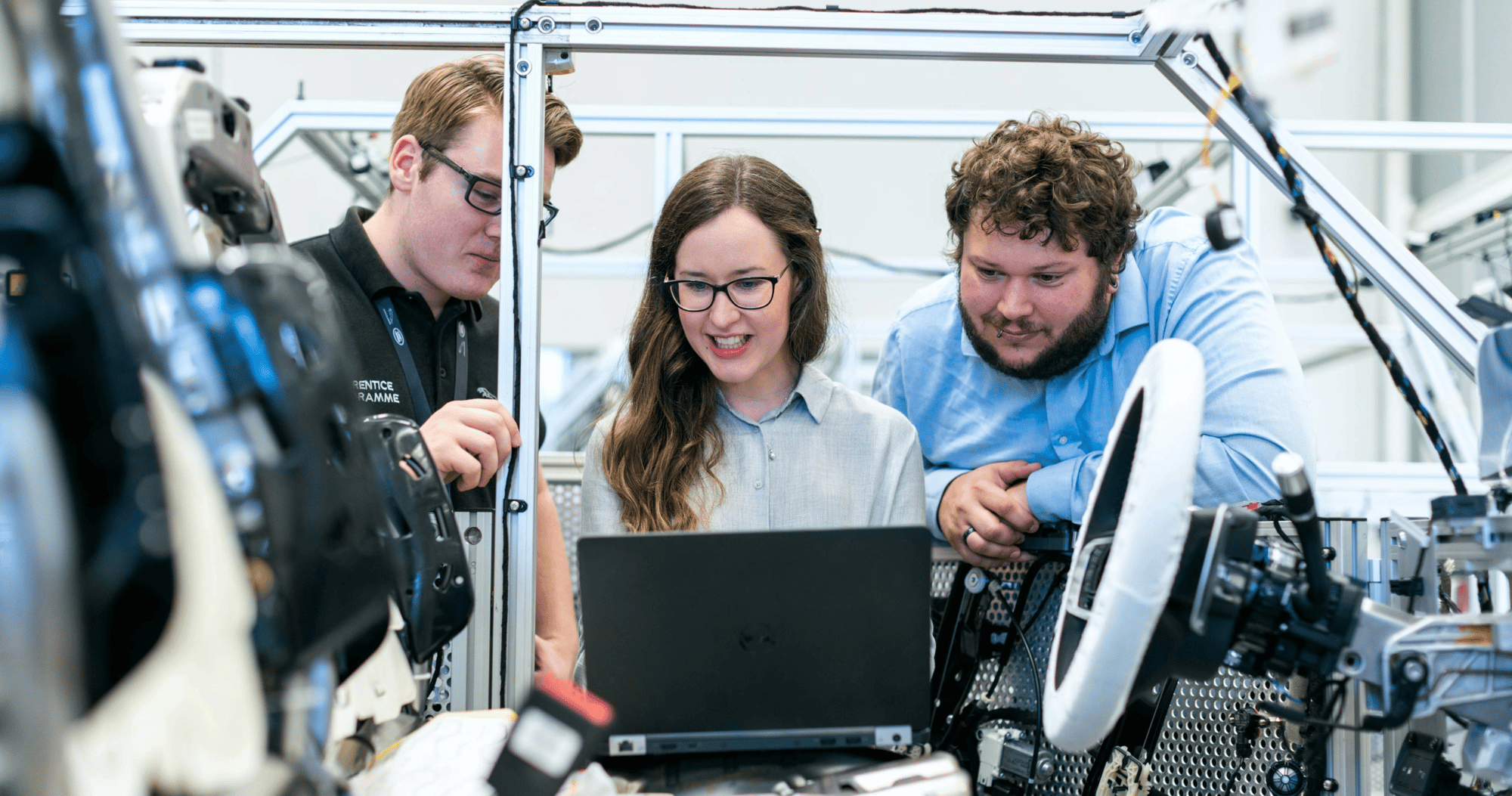

CeLLife for Automation system providers

.png?width=2000&height=1053&name=Untitled-6%20(1).png)

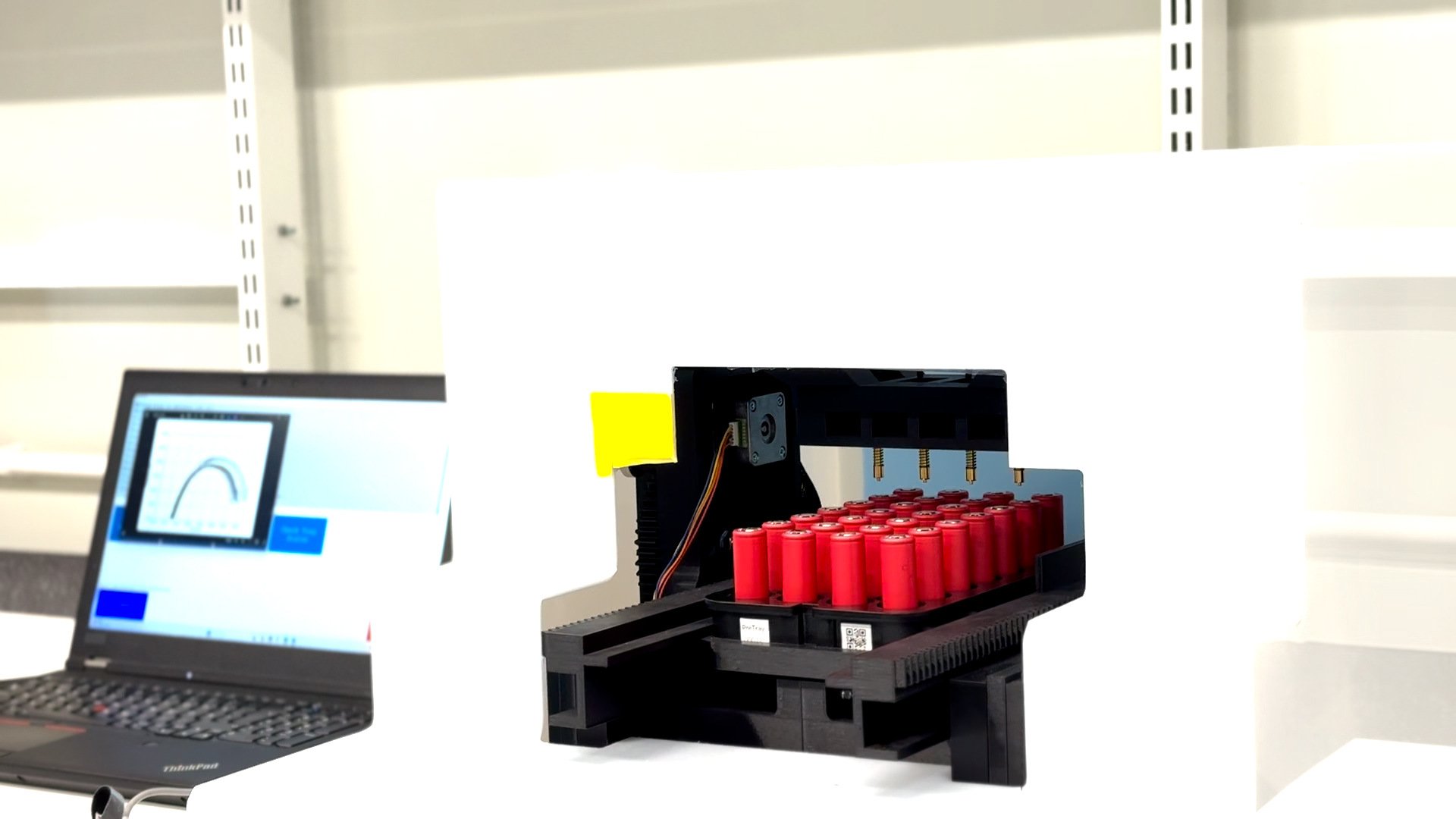

1. Configure CeLLife solution to production needs

Together with our experts, we help you install CeLLife solution to your production or module assembly line. While the measurement technique is always the same, the underlying CeLLife AI is fine-tuned to detect the most relevant defects, ensuring accurate and meaningful diagnostics.

2. Make informed data-driven decisions in real-time

CeLLife AI delivers instant diagnostic results for each cell on the production line, enabling data-driven decision-making. This rapid feedback ensures that only high-quality cells move forward. All measurement data is logged, providing a reliable foundation for process monitoring and quality control.

3. Identify and fix the underlying root causes

Beyond real-time diagnostics, CeLLife combines measurement data, diagnostic results, and your process data to identify trends and pinpoint inefficiencies. By analyzing these insights, production process parameters can be refined to improve overall battery quality and production efficiency